Data Cable Equipment

For further information on any of our product or services, please contact us via the Feedback facility.

Twinning

Twinning of telephone or data cable pairs can be carried out at high speed on our smaller double twist machines. For Cat 5, 6 & 7 LAN cable it is important that the short lay and tension is controlled to accurate limits, and the use of mechanical lay gears is much preferred.

A typical twinning line comprises a B450, 500, 560 or 630 machine with two tension controlled core input stands.

Laying up twins

For many simpler products this can be done on another double twist machine – commonly the SLB 800E machine where the reel capacity matches that of the 4 input twins on 560 or 630 reels

This is known as the two stage process – twinning then laying up with separate machines, and it has advantages of excellent flexibility of equipment, optimisation of the machine outputs and relatively low capital costs.

Taping units can be added to the machines at either the twinning or laying up stage

For many higher quality cables, for multiple tapes or larger bundles of data cables, the laying up is best done with a single twist machine

Our range of single twist machines offer both the highest rotational speeds with good tension control, and options for the capstan configuration to suit many complex cable constructions

Backtwist

The performance of Cat 6 and above cables can be improved by backtwisting the core prior to twinning to counteract any damaging effect of the twist imparted in each individual core. Our Backtwist Pay Off unit is compact and allows a variable degree of backtwist around the optimum 35 - 40% used in many plants. We can supply with either simple mechanical tensioning, or with electronic tensioning. Along with a B560/630 twinner the very best performance twin can be produced

The benefits of backtwist and high speed quality twinning are combined in Northampton’s new compact TT560/630 machine for the higher category cables:

| Small footprint/compact layout | |

| Very high outputs due to accumulative twisting | |

| Variable backtwist is inbuilt | |

| Easy reel load/unload | |

| Full electronic synchronization to allow accurate tuning of lay lengths |

A revolution in performance enhancement

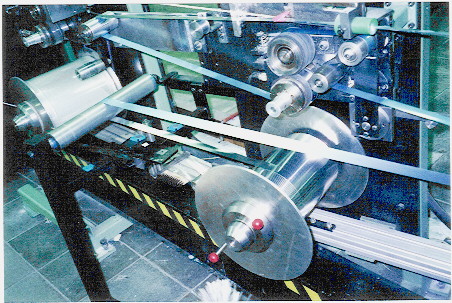

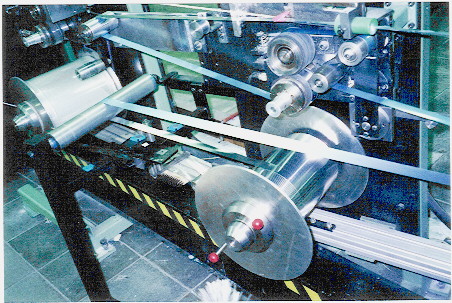

Group Twinner

| |

|  |

| |

For certain products and environments the movement of materials can be reduced using the single stage ‘Group Twinning’ process.

This has long been used for telephone cables, but Northampton Machinery designed the very first horizontal High Speed Group Twinner specifically for short lay Category cable. This machine combines:

| Small throw bow with easy wire path for minimum tension at speed | |

| High speed Single Twist take up for maximum linear speed on long lay product | |

| Speeds of up to 4400 twists/min on twinning and 850 rpm single twist | |

| Electronically synchronised speed and lay controls for fine tuning performance cables |